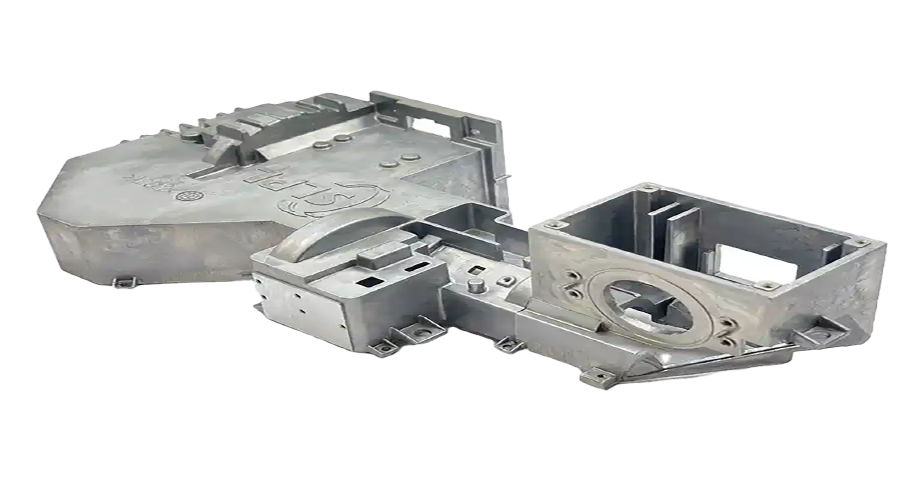

Die Casting Service

Die casting delivers durable, high-accuracy metal components used across a wide range of industries.

NDA available upon request before quoting.

Why choose die casting

Die casting is a high-efficiency manufacturing process used to produce large volumes of precision metal components with complex geometries and fine surface details. The process involves injecting molten metal under high pressure into a steel mold, or die, where it rapidly cools and solidifies to form the final part. Known for its dimensional accuracy, smooth surface finish, and repeatability, die casting is widely applied in industries such as automotive, aerospace, and electronics. There are two primary types of die casting: hot chamber and cold chamber. Hot chamber die casting is ideal for low-melting-point metals like zinc and magnesium, offering faster cycle times, while cold chamber die casting is used for higher-melting-point metals such as aluminum and brass, requiring a separate melting process. Both methods enable the production of strong, precise parts suitable for demanding industrial applications.

Commonly used materials for die casting

Our core die casting materials include aluminum, zinc, magnesium, and copper-based alloys, each selected for their specific mechanical properties, thermal behavior, and casting performance. These materials offer optimal strength-to-weight ratios, corrosion resistance, and dimensional stability—making them ideal for high-precision tooling and complex mold geometries.

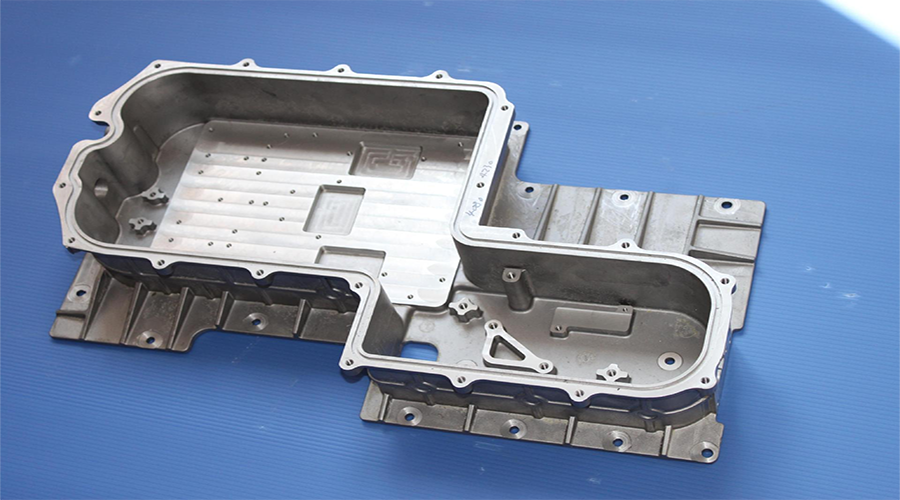

Aluminum Die Casting

Aluminum alloys are widely utilized in die casting for their excellent strength-to-weight ratio,

Aluminum ADC12、ADC6、A360、A380

Zinc Die Casting

With superior toughness and castability, zinc enables the production of complex, high-precision components built for long-term performance

Zinc Zamak 3, Zamak 5, Zamak 2, ZA8

Magnesium Die Casting

Magnesium is the lightest structural alloy available, delivering excellent rigidity relative to its weight—an ideal choice for applications demanding both strength and minimal mass.

Magnesium AZ91D, AM60B

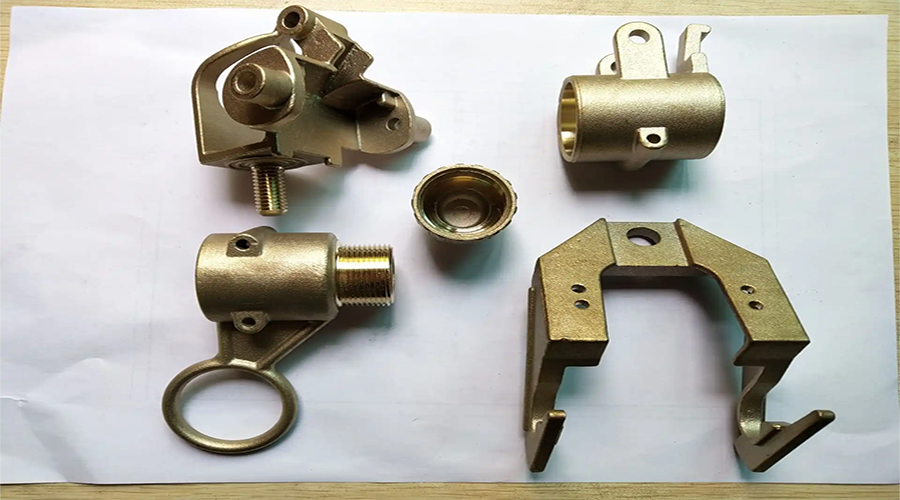

Copper Die Casting

Thanks to its excellent heat and electrical conduction performance, copper is commonly used in precision cast parts like heat sinks, terminals, and power components where energy efficiency is critical.

Copper ZQA19-2, ZQA19-4, ZQA19-7, ZQA19-10

Mazaro Production Capacity

| Minimum Part Weight | 0.017 kg |

| Maximum Part Weight | 12 kg |

| Minimum Part Size | Ø17 mm × 4 mm |

| Maximum Part Size | 300 mm × 650 mm |

| Minimum Wall Thickness | 0.8 mm |

| Maximum Wall Thickness | 12.7 mm |

| Quality Control | ISO 9001 Certified |

| Minimum Order Quantity | 1000 pcs |