Rapid Prototyping Service

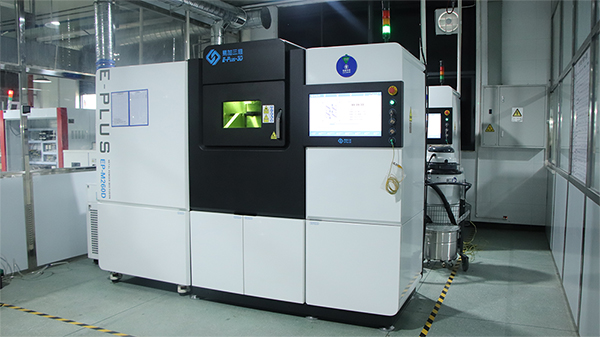

Rapid prototyping is a critical stage in the product development cycle, enabling the transformation of 3D CAD models into functional physical prototypes using advanced manufacturing processes. we specialize in high-precision rapid prototyping techniques including CNC milling and turning, additive manufacturing (3D printing), and silicone vacuum casting.

NDA available upon request before quoting.

Rapid Prototype At KingStar Mold

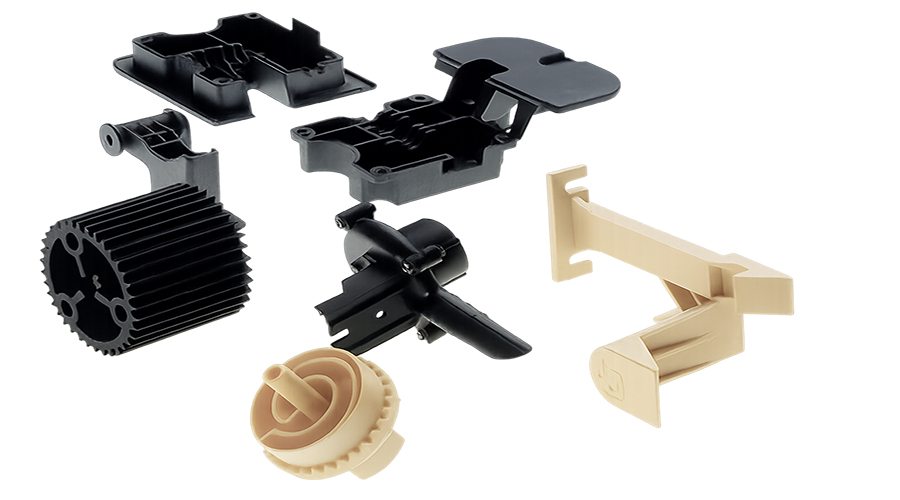

Providing High-precision Prototypes

- Metal prototypes

- Sheet metal prototypes

- Appliance prototypes

- Automotive prototypes

- Metal prototypes

- Robotics prototypes

- Electronic prototypes

- Plastic prototypes

Main Rapid Prototyping Services At KingStar Mold

High stability and good surface quality, capable of quickly and accurately producing samples similar to the final product.

Our main advantages in rapid prototyping

Improved Design Accuracy

- Create precise prototypes that mirror the final product.

- Identify potential design flaws early in the process.

- Ensure that prototypes meet your exact specifications and requirements.

Enhanced Flexibility and Iteration

- Quickly modify designs based on testing results.

- Easily try out new ideas or features in your product.

- Refine and improve prototypes without starting from scratch.

Faster Time-to-Market

- Quickly turn your design concepts into physical prototypes.

- Accelerate the feedback loop with rapid testing and evaluation.

- Reduce delays and get products to market faster.

Cost Efficiency

- Save on the high costs of traditional manufacturing methods.

- Reduce waste by refining designs before mass production.

- Minimize expensive revisions with more efficient prototyping.