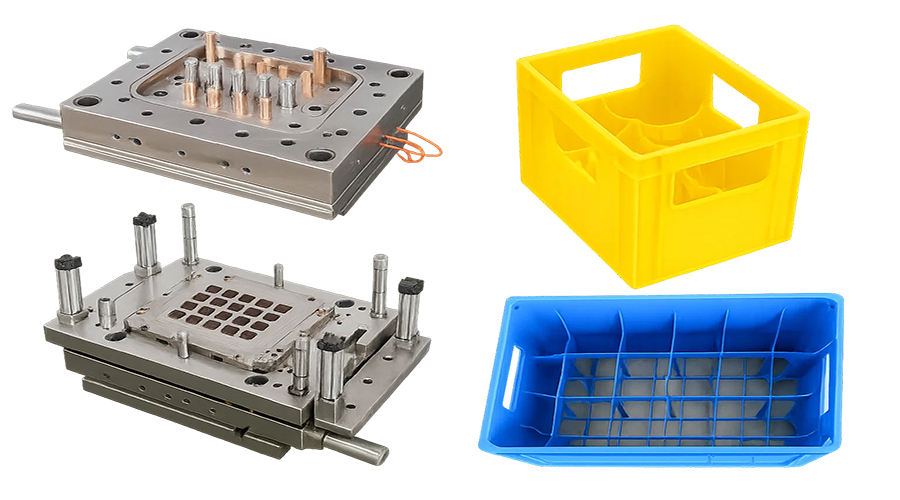

Precision-Molded Plastics, Tailored to Fit Your Vision—Fast, Reliable, Scalable

Experience global-quality precision with our expert plastic injection molding services—engineered for accuracy and consistency. From rapid prototyping to high-volume production, . Your one-stop solution for scalable, on-demand manufacturing.

NDA available upon request before quoting.

Mold Making Materials

Mold manufacturing utilizes a range of specialized materials, including mold steel, custom alloys, and other high-performance substances. The selection of materials is critical to ensuring the quality and longevity of the mold. High-quality mold materials contribute to the precision and stability of the mold over time, directly impacting its ability to produce consistent and accurate results. Additionally, the choice of materials plays a key role in the performance of injection molding, helping to produce high-quality plastic products with minimal defects.

Brief Understanding of Mold Making Materials

Improved Communication:

A basic understanding of mold-making materials enhances communication between customers and manufacturers, leading to more accurate and clear specifications.Informed Material Selection:

Knowledge of materials allows customers to make well-informed choices, considering their product’s performance, cost, and quality requirements.Setting Realistic Expectations:

Understanding mold materials helps customers establish realistic expectations regarding product performance and limitations, ensuring alignment with manufacturing capabilities.Cost and Supply Chain Planning:

A clear grasp of mold-making materials enables customers to better understand manufacturing costs and potential supply chain challenges, helping them plan ahead and manage production timelines efficiently.

| Material Type | Common Performance | Features | Typical Applications |

|---|---|---|---|

| Stainless Steel | 420 | Corrosion-resistant, Hardenable | Medical or food-grade molds |

| 6061 | Strength, Good welding combination | Non-critical parts, mold frames | Non-critical parts, mold frames |

| Carbon Steel | 1018 | Good machinability, Low cost | Prototype molds |

| Aluminum Alloy | ZA-12 | Good strength, Lower cost compared to steel | Die casting molds |

| Pre-hardened Steel | 4140 | Good toughness, High fatigue strength | Gears, Automotive molds |

| Tool Steel | 52100 | High hardness, Wear-resistant | High-precision bearings, molds |

| High-speed Steel | M2 | High heat resistance, Wear-resistant | High-precision molds, Cutting tools |

| 17-4PH | High strength, Excellent corrosion resistance | Aerospace, Automotive molds | Aerospace, Automotive molds |

| Aluminum | 7075 | High strength, Lightweight | Prototypes, Small batch molds |

| Alloy Steel | Alloy 25 | High thermal conductivity, Strength | Cooling components, Hot runner systems |

| 4340 | High toughness, High strength | Large mold requiring cutting ability | Large mold requiring cutting ability |

| D2 | High wear resistance | Die molds | Small batch production molds |

| 1045 | High strength medium carbon steel | Hot work steel, Good cutting ability | Mass injection molds |

| H13 | Hot work steel, Good cutting ability | Mass injection molds | Mass injection molds |

| P20 | Pre-hardened, Good polishability | General-purpose molds | Common molds |

| S7 | Shock-resistant | Required for high-impact molds | High-impact molds |