Precision CNC Turning Services for Complex Rotational Parts

CNC Turning for High-Precision, Durable Rotational Components

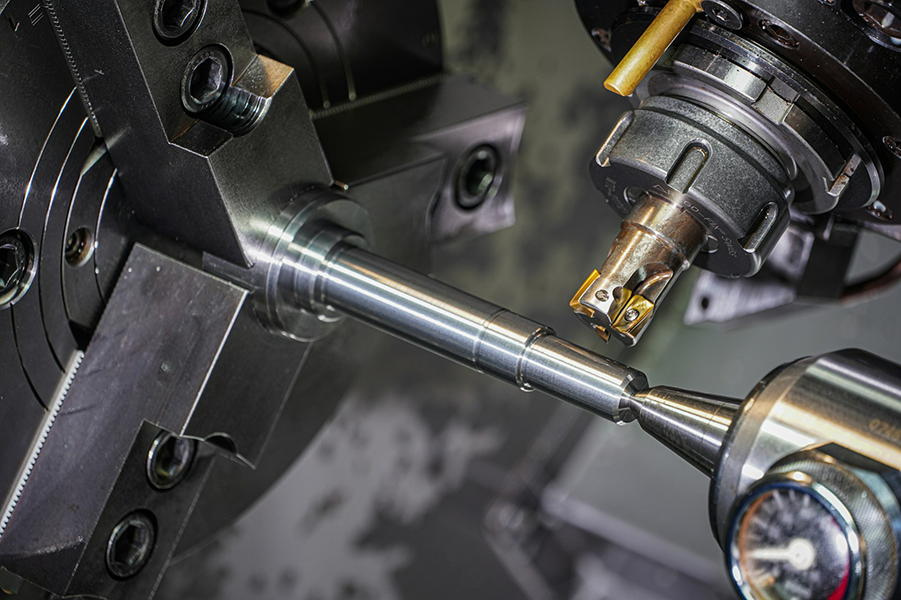

Engineered for the efficient machining of long, cylindrical, and threaded parts, our CNC turning process delivers exceptional dimensional accuracy and repeatability. Advanced turning centers ensure tight tolerances, excellent surface finishes, and geometric symmetry—ideal for producing components such as shafts, pins, bushings, and threaded fittings across various industries.

NDA available upon request before quoting.

Dependable CNC Turning Solutions for Superior Quality Components

Our CNC turning services are engineered to produce high-quality custom components with rapid turnaround times. Leveraging state-of-the-art equipment and a team of skilled technicians, we achieve tight tolerances and handle complex geometries with ease. We specialize in precision components such as shafts, bushings, couplings, and threaded parts, utilizing a wide range of materials—including aluminum, brass, steel, and more. Choose our CNC turning services to experience our unwavering commitment to quality, reliability, and precision craftsmanship, ensuring your project meets the highest standards of performance.

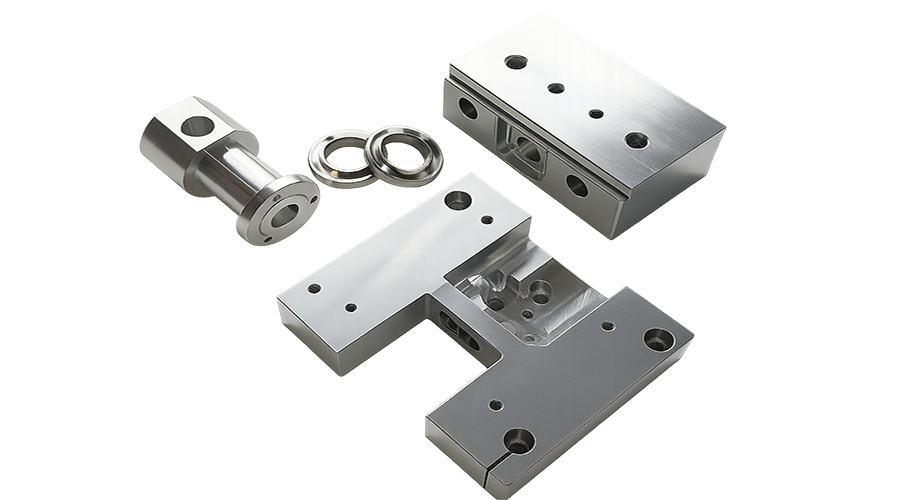

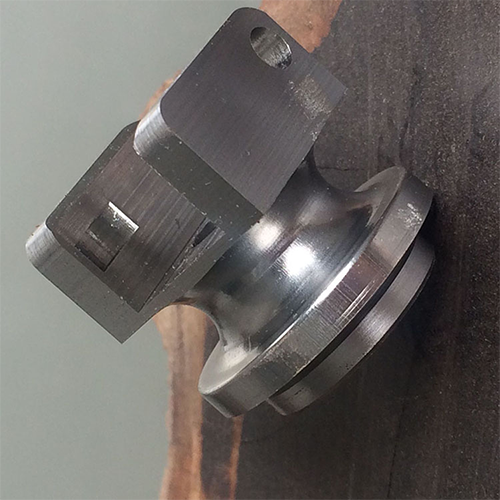

Gallery of Turned Components

By reviewing the case study below, you can gain a deeper insight into our CNC turning process.

Why Partner with Us for Your CNC Machining Needs?

Flexible Pricing & Instant Quotes

• Receive accurate, no-obligation quotes in minutes.

• Tiered pricing structures that adapt to both prototype and production budgets.Unrivaled Precision & Reliability

• Multi‑axis CNC milling and turning delivering tolerances down to ±0.001″.

• High‑speed machining ensures rapid cycle times without compromising part integrity.Robust Quality Assurance

• Complete metrology suite: CMM, pin gauges, micrometers, roughness testers, projectors, and concentricity measurement tools.

• In‑process inspections and final validation guarantee every part meets your exact specifications.Extensive Materials & Finishes

• Machine over 50 metals and engineering plastics—from aluminum and stainless steel to PEEK and nylon.

• Choose from 10+ surface treatments (anodizing, plating, powder coating, bead blasting, polishing, and more) to achieve smooth surfaces and strict tolerances.

• Custom material selections and specialized coatings available on demand.Scalable Efficiency

• Lean manufacturing workflows optimized for low, medium, and high‑volume runs.

• Rapid prototyping through end‑use production—seamless transition from design to delivery.

• High throughput and reduced lead times deliver faster time‑to‑market.

CNC Machining Accuracy Standards

mazaro offers diverse CNC machining capabilities to accommodate a broad range of requirements.

1. Size

Threaded Holes

UNC & UNF threads from #2 up to 0.5 in.

Metric threads M1.2 and above.

Radii

Turned outside corners will typically include a 0.005 in. chamfer.

Minimum hole size:

- Minimum on-axis and axial: 0.04 in. (1mm)

- Minimum radial: 0.08 in. (0.5mm), 0.04 in. (0.5mm) for aluminum and brass

Grooves:

- Minimum OD groove width: 0.047 in. (1.2mm)

- Minimum OD groove width for aluminum and brass: 0.019 in. (0.5mm)

- Maximum OD groove depth: 0.95 in. (24.1mm) — varies with groove width

| Linear dimension | +/- 0.025mm +/- 0.001 inches |

|---|---|

| Hole diameter (not reamed) | +/- 0.025mm +/- 0.001 inches |

| Shaft diameter | +/- 0.025mm +/- 0.001 inches |

| Part Dimension limit | 950*550*480mm 37.0 * 21.5 * 18.5 inches |

CNC Machining Specifications

| Tolerance class | tolerance (mm) Metal (ISO 2768-F) | tolerance (mm) Plastic (ISO 2768-F) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

Fundamental Tolerances for Form and Position

| Tolerance class | tolerance (mm) Straightness and Flatness | tolerance (mm) Verticality | tolerance (mm) Symmetry | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | |

| H | ±0.02 | ±0.05 | ±0.1 | ±0.2 | ±0.3 | ±0.4 | ±0.2 | ±0.3 | ±0.4 | ±0.5 | ±0.5 | ±0.5 | ±0.5 | |

CNC Milling Materials at mazaro– Our Material Expertise

mazaro’s CNC milling services accommodate a broad spectrum of substrates, from metals and plastics to woods. Each material category demands tailored tooling, feeds, and speeds—and specific maintenance and safety protocols—to ensure optimal results. Below is a list of commonly machined materials; if your required material isn’t listed, please reach out to us for a custom solution.

| Material | Available Types & Grades |

|---|---|

| Aluminum |

Aluminum 2024 Aluminum 5052 Aluminum 5083 Aluminum 6063 Aluminum 6061 Aluminum 6082 Aluminum 7050 Aluminum 7075 |

| Brass/Bronze |

Brass C360 Brass 260 C932 M07 Bearing Bronze |

| Copper |

Copper C110 Copper 101 |

| Steel |

Alloy Steel 4130 Alloy Steel 4140 Mild Steel 1018 Mild Steel A36 |

| Stainless Steel |

Stainless Steel 17-4 Stainless Steel 18-8 Stainless Steel 303 Stainless Steel 304/304L Stainless Steel 316/316L Stainless Steel 416 Stainless Steel 420 |

| Titanium |

Titanium Grade 2 Titanium Grade 5 |

| Plastics |

ABS Nylon POM PEEK PMMA PTFE Polystyrene Polyethylene Polycarbonate |

CNC Milling Surface Finishes at our– Enhance Performance and Appearance with Expert Finishing Solutions

we offer a diverse range of surface finishing options for CNC-milled parts, tailored to improve both functional and visual properties. Whether you’re aiming to enhance surface aesthetics, increase corrosion resistance, or achieve a smoother finish, our finishing processes are designed to meet your specific requirements. Choose from a variety of metal finishing techniques to optimize durability, precision, and overall part quality.

| Surface Finish | Description |

|---|---|

| As machined | Standard finish with a surface roughness of 1.6 µm (126 µin). |

| Smoothing | The standard smoothing surface roughness (Ra) is 0.8 µm (63 µin). |

| Painting | Spraying paint, pigment, or color to a solid surface as a colored protective layer. |

| Passivation | Remove ferrous contaminants or use a light coat of protective material to create a shell. |

| Powder Coating | A functional and decorative finish that is applied as a free-flowing, dry powder. |

| Anodizing | Type II (anodizing color or clear) or Type III (anodizing hard coat). |

| Polishing | Produce a smooth and shiny surface. |

| Black Oxide | Forming a black conversion coating on metal parts. |

| Bead Blasting | Removing surface deposits by applying fine glass beads at a high pressure. |

| Abrasive Blasting/Sandblasting | Smoothing and cleaning a hard surface by forcing solid particles across that surface. |

| Electroplating/Plating | Form a thin coherent metal coating on an electrode. |

| Brushing | Polishing the metal with grit resulting in a unidirectional satin finish. |

| Chromate Conversion Coating | Increase the corrosion resistance while maintaining conductive properties. |