High-Precision CNC Milling Solutions for International Clients

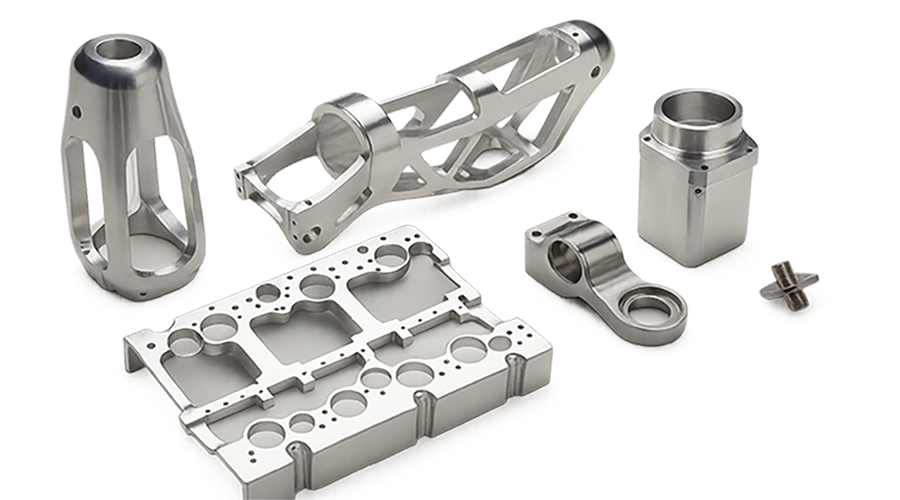

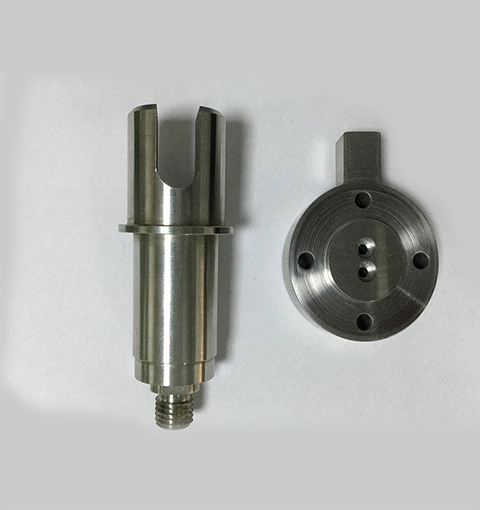

Experience one of the most dependable CNC milling services available. From initial concept to final product, our well-established production system ensures full-process reliability, enabling the efficient manufacturing of highly customized and precise components.

NDA available upon request before quoting.

High-End CNC Milling Solutions – Leading Manufacturer of Precision Milled Components in China

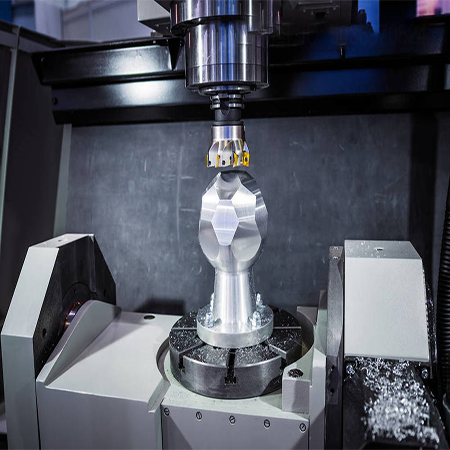

Looking for cost-effective CNC milling parts without compromising quality? Junying Metal Manufacturing Co., Limited is a leading CNC service provider in China, delivering superior precision milling solutions. We utilize state-of-the-art machinery—including advanced CMC milling centers and high-performance milling machining centers ranging from 3-axis to 5-axis systems—operated by highly skilled machinists. Our experienced team, proficient in CAD and CAM technologies, is dedicated to optimizing production processes to manufacture the highest quality CNC-milled parts and components.

Leveraging robust capabilities and extensive industry experience, we offer top-grade, custom CNC milling services that are both cost-effective and reliable. Our services include 3-axis and 5-axis CNC milling tailored for high-speed manufacturing, rapid prototyping, and precision milling and turning. Our high-quality rapid CNC milling products serve a wide array of industries, from automation design and locksets to automotive parts, machinery components, defense systems, medical equipment, and lighting assemblies. Send us your inquiry or design drawings today for an instant online CNC quote.

Industries Served by Our CNC Milling Solutions

Advanced CNC Milling Specifications and Core Competencies

Rapid Quotation & Competitive Pricing:

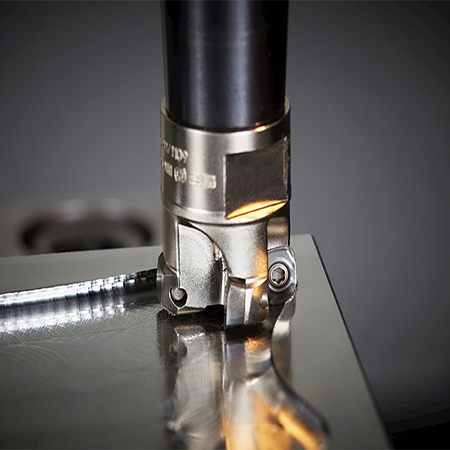

Benefit from our fast quote system and flexible pricing models, designed to accommodate projects of all scales—from prototyping to high-volume production—while ensuring cost-effectiveness.Unmatched Precision & Efficiency:

Our state-of-the-art CNC technology delivers high dimensional accuracy, exceptional speed, and reliable performance, ensuring every part meets stringent quality standards.Comprehensive Quality Assurance:

Equipped with advanced metrology tools such as CMM, pin gauges, roughness testers, projectors, micrometers, and concentricity measurement devices, we guarantee that every component adheres to your precise specifications.Rapid Prototyping to End-Use Production:

We offer an end-to-end service—from rapid prototyping to full-scale production—allowing for seamless transition from concept design to market-ready products.Diverse Material & Finishing Options:

Choose from over 50 types of metals and plastics, paired with more than 10 surface finish options. We provide custom material formulations and surface treatments to achieve smooth surfaces and maintain strict tolerances.Scalable Production Capabilities:

Our advanced processes and robust infrastructure support low, medium, and high-volume production runs, ensuring high productivity and improved efficiency throughout your project lifecycle.

Distinct Advantages and Key Benefits of Our Milling Services

Precision

Our 3-axis, 4-axis, and 5-axis CNC milling machines deliver exceptional precision and accuracy, achieving tolerances within ±0.001″. This level of precision is essential for industries like aerospace, medical, and automotive, where exact measurements are crucial.

Pace or Efficiency

With over 60 milling machines and a team of experienced machinists, we are able to produce parts swiftly and efficiently, ensuring top-quality results every time.

Economically Efficient

Leveraging our efficient processes and cutting-edge machinery, we deliver affordable milling solutions while maintaining high standards of quality and precision.

Complex Geometric Designs

Our CNC milling service is perfect for manufacturing detailed parts with complex shapes, including slots, grooves, and other bespoke features.

Design Flexibility

Our skilled engineers and machinists offer design recommendations to enhance your parts for efficient production and can quickly manufacture low-volume, custom parts with fast turnaround times.

Wide Range of Materials

We offer milling services for a broad selection of materials, including metals, plastics, and composites, tailored to meet your unique requirements.

CNC Milling Materials - Materials Used for CNC Milling Services

| Material Type | Available Types & Grades |

|---|---|

| Aluminum | Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6061, Aluminum 6082, Aluminum 7050, Aluminum 7075 |

| Brass/Bronze | Brass C360, Brass 260, C932 M07 Bearing Bronze |

| Copper | Copper C110, Copper 101 |

| Steel | Alloy Steel 4130, Alloy Steel 4140, Mild Steel 1018, Mild Steel A36 |

| Stainless Steel | Stainless Steel 17-4, Stainless Steel 18-8, Stainless Steel 303, Stainless Steel 304/304L, Stainless Steel 316/316L, Stainless Steel 416, Stainless Steel 420 |

| Titanium | Titanium Grade 2, Titanium Grade 5 |

| Plastics | ABS, Nylon, POM, PEEK, PMMA, PTFE, Polystyrene, Polyethylene, Polycarbonate |

CNC Milling Surface Finishes – Enhancing the Quality of Milled Parts

We offer a diverse range of metal surface finishing options for CNC milled parts, designed to enhance their appearance, smoothness, corrosion resistance, and other essential properties.

| Surface Finish | Description |

|---|---|

| As Machined | Standard finish with a surface roughness of 1.6 μm (126 μin). |

| Smoothing | The standard smoothing surface roughness (Ra) is 0.8 μm (63 μin). |

| Painting | Spraying paint, pigment, or color to a solid surface as a colored protective layer. |

| Passivation | Remove ferrous contaminants or use a light coat of protective material to create a shell. |

| Powder Coating | A functional and decorative finish that is applied as a free-flowing, dry powder. |

| Anodizing | Type II (anodizing color or clear) or Type III (anodizing hard coat). |

| Polishing | Produce a smooth and shiny surface. |

| Black Oxide | Forming a black conversion coating on metal parts. |

| Bead Blasting | Removing surface deposits by applying fine glass beads at high pressure. |

| Abrasive Blasting/Sandblasting | Smoothing and cleaning a hard surface by forcing solid particles across that surface. |

| Electroplating/Plating | Form a thin coherent metal coating on an electrode. |

| Brushing | Polishing the metal with grit resulting in a unidirectional satin finish. |

| Chromate Conversion Coating | Increase the corrosion resistance while maintaining conductive properties. |