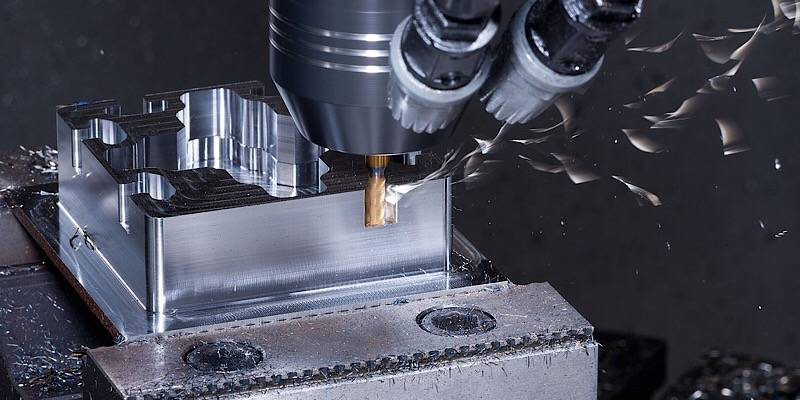

Precision CNC Stainless Steel Machining – Durable, Corrosion-Resistant Parts Tailored to Your Needs

Our advanced 3-axis and 5-axis CNC machining centers deliver exceptionally tight tolerances on custom turning, milling, drilling, and prototyping jobs—all at competitive prices. Backed by a seasoned technical team with deep expertise in stainless steel workflows and a state-of-the-art facility, we ensure rapid turnaround and consistent, top-quality results for your most demanding applications

NDA available upon request before quoting.

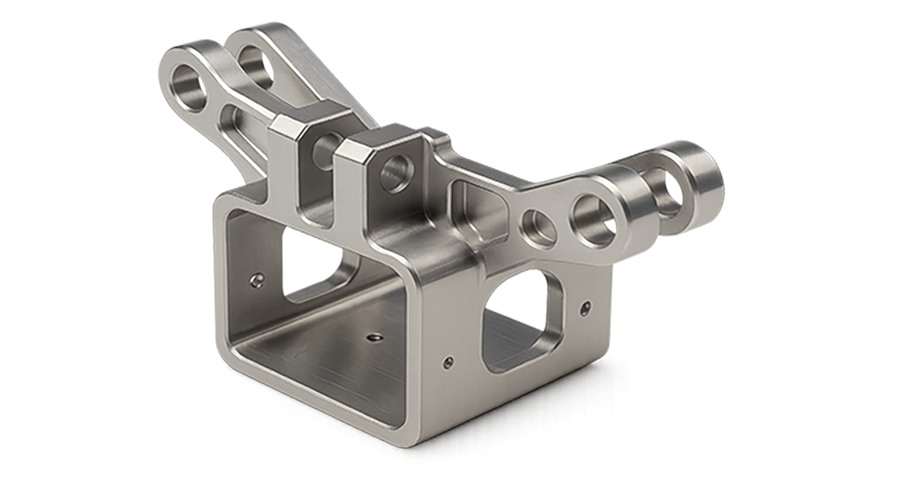

High Precision Stainless Steel CNC Machining Services

At Mazaro Machining, we excel in precision stainless steel machining, offering comprehensive services that encompass both turning and milling operations. Our advanced Swiss turning centers are specifically designed to efficiently and accurately produce small, intricate components, making them ideal for high-volume production runs. Additionally, our state-of-the-art equipment is capable of handling larger and more complex parts, ensuring exceptional quality and precision across a diverse range of sizes and geometries.

By choosing Mazaro’s stainless steel machining services, you partner with a team committed to precision, quality, and reliability. Our expertise spans various industries, including aerospace, automotive, medical, and more, enabling us to deliver stainless steel components that not only meet but often exceed your expectations. We invite you to contact us to discuss your specific machining requirements and to experience the Mazaro advantage in stainless steel engineering firsthand.

Key Advantages of Stainless Steel in CNC Machining Applications:

Exceptional Corrosion Resistance: Stainless steel offers excellent resistance to rust and oxidation, ensuring longevity and reliability in harsh environments.

Robust Strength and Durability: Its superior mechanical properties enable it to withstand high stress and impact, making it ideal for demanding applications.

Precision Machinability: Consistent material properties and excellent machinability allow for tight tolerances and intricate designs using CNC processes.

Aesthetic and Hygienic Finish: The smooth, clean surface finish not only enhances visual appeal but also meets stringent hygiene standards, crucial for medical and food processing industries.

Eco-Friendly and Recyclable: As a fully recyclable material, stainless steel supports sustainable manufacturing practices while maintaining high performance.

Precision CNC stainless steel parts display

Extensive Selection of CNC Stainless Steel Materials

Precipitation-Hardening Stainless Steels:

Stainless Steel 15-5:

High strength with good toughness

Excellent corrosion resistance

Superior machinability in the annealed state

Stainless Steel 17-4 (also known as Stainless Steel 630):

High strength and fatigue resistance

Excellent corrosion resistance after precipitation hardening

Widely used in aerospace and industrial applications

Austenitic Stainless Steels:

Stainless Steel 18-8:

General designation for austenitic stainless steels (often related to 304/304L)

Offers balanced strength and corrosion resistance

Good formability and weldability

Stainless Steel 304/304L:

Excellent corrosion resistance and oxidation resistance

Superior weldability and formability

Widely used in a broad range of industries

Stainless Steel 316/316L:

Enhanced corrosion resistance, particularly in chloride environments

Ideal for marine, chemical processing, and medical applications

Provides excellent strength and durability

Free-Machining Austenitic Stainless Steel:

Stainless Steel 303:

Specifically modified for improved machinability

Suitable for parts requiring complex machining operations

Maintains good strength with moderate corrosion resistance

Martensitic Stainless Steels:

Stainless Steel 416:

Optimized for superior machinability (often via sulfur addition)

Provides moderate corrosion resistance

Used where intricate machining is required

Stainless Steel 420:

Capable of being hardened for high surface hardness

Good corrosion resistance in certain environments

Commonly used in cutlery and surgical instruments

Stainless Steel 440C:

Exceptional hardness and wear resistance

Ideal for precision components such as bearings and high-performance tools

Ferritic Stainless Steels:

Stainless Steel 431:

Offers good strength and high corrosion resistance

Suitable for heavy-duty applications where durability is paramount