Precision Copper CNC Machining | China’s Premier Supplier of Custom Copper Components

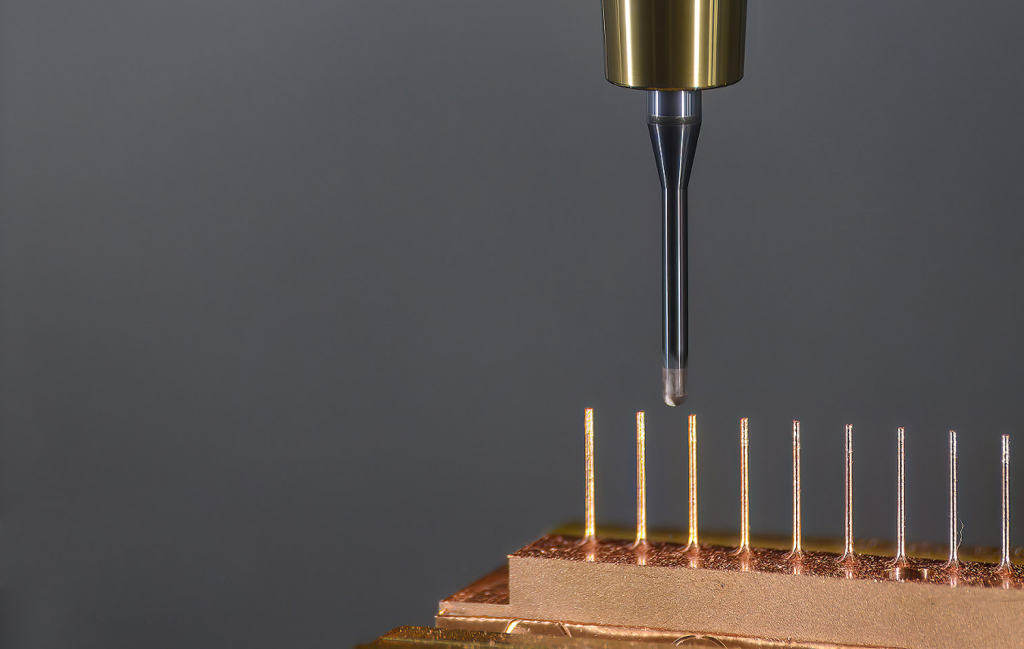

Our full-spectrum services include CNC milling, turning, and wire EDM, complemented by premium finishes such as electroplating and electropolishing, to meet the exacting needs of electronics, automotive, power generation, and industrial markets.

NDA available upon request before quoting.

Precision CNC Machining for the Medical Industry

mazaro is a premier CNC machining manufacturer in China with extensive expertise in producing high-precision medical parts for surgical instruments and devices. Leveraging state-of-the-art technology and advanced equipment, we have established ourselves as one of the nation’s largest and most reliable providers of CNC-machined medical components. We offer customized prototyping and production services for performance-critical medical parts, addressing the demanding needs of high-volume, high-precision medical equipment. Our commitment to high-speed, intelligent processing and environmentally friendly practices ensures that we consistently deliver superior, precision-engineered medical products on time and at competitive rates.

Safety, Precision and Quality First

Precision CNC Machining Capabilities for Medical Parts

Precision & Accuracy:

Achieves tight tolerances and high repeatability, ensuring consistent quality of critical medical components.

Customization & Complexity:

Enables the fabrication of complex geometries and intricate designs tailored to specific medical applications.

Material Versatility:

Supports a wide range of materials including biocompatible metals, high-performance plastics, and specialized alloys, meeting diverse application needs.

Rapid Prototyping & Short Lead Times:

Facilitates fast turnaround for prototyping and iterative testing, accelerating product development and time-to-market.

Cost-Effectiveness:

Scalable production methods make CNC machining economical for both low- and high-volume manufacturing.

Enhanced Surface Finishing:

Allows for precise surface treatments that improve biocompatibility, corrosion resistance, and overall component performance.

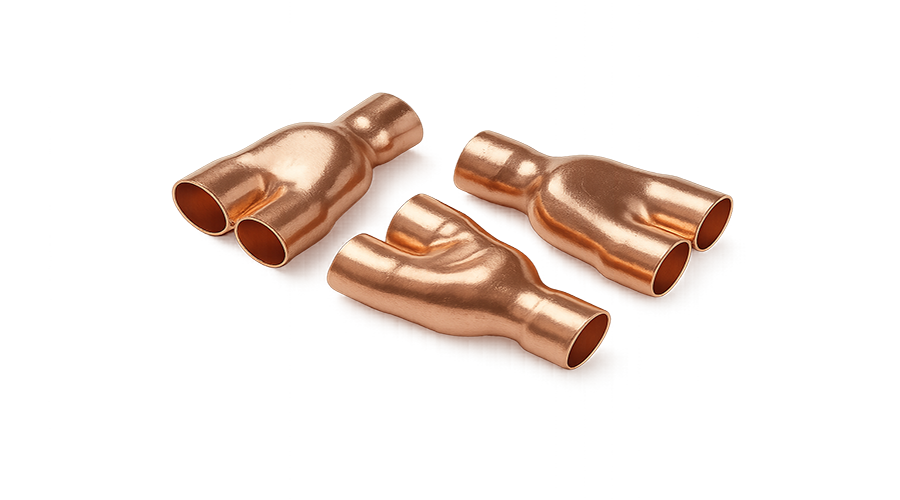

of Copper Alloys in CNC Machining

Two copper alloys are frequently utilized in CNC machining due to their exceptional electrical and thermal conductivity, making them highly favored in industries such as automotive, medical, aerospace, and power generation.

Copper C101: Also known as C10100 or CDA 101, this oxygen-free copper alloy contains approximately 99.95% copper. Its high purity delivers excellent electrical and thermal conductivity, along with impressive ductility and impact strength. Consequently, Copper C101 is widely applied in automotive rectifiers, coaxial cables, bus bars, conductors, and vacuum seals.

Copper C110: Also referred to as UNS C11000 or CDA 110, this alloy is among the purest, with a copper content of around 99.99%. In addition to its outstanding electrical and thermal conductivity, Copper C110 exhibits superior corrosion resistance, high ductility, and excellent formability for both hot and cold working processes. It is commonly used in cables, overhead line conductors, generator windings, and coaxial lines.

Key Properties and Applications of Common Copper and Copper Alloys

| C10100 | It has excellent cold and hot working properties and good forgeability. Can be used as busbars, waveguides, lead wires… |

| C11000 | Both cold and hot processing properties are excellent. Mainly used as building materials, automobile radiators… |

| C12000 | Both cold and hot processing properties are excellent. Mainly used for bus bars, wires… |

| C14500 | Both cold and hot processing properties are excellent. Mainly used for forgings and threaded parts… |

| C17200 | The performance and use are the same as C17000 beryllium bronze, and it has the characteristics of non-sparking… |

| C18200 | Excellent cold workability and good hot workability. Mainly used as resistance welding electrodes… |

| C20500 | Mechanical properties: It has good stretchability and high toughness. It is mainly used in the fluid equipment industry… |

| C26000 | It has excellent cold working properties and is mainly used as radiator fins, refrigerators, cartridge cases… |

| C36000 | Excellent cutting performance, mainly used for gears and high-speed automatic cutting parts… |

| C38500 | It has excellent cutting and hot workability, and is mainly used as building profiles, door and window frames… |

| C46400 | It has excellent hot workability and is mainly used as joint parts on aircraft, small hardware on ships… |

| C93200 | Universal Bearings and Bushings |