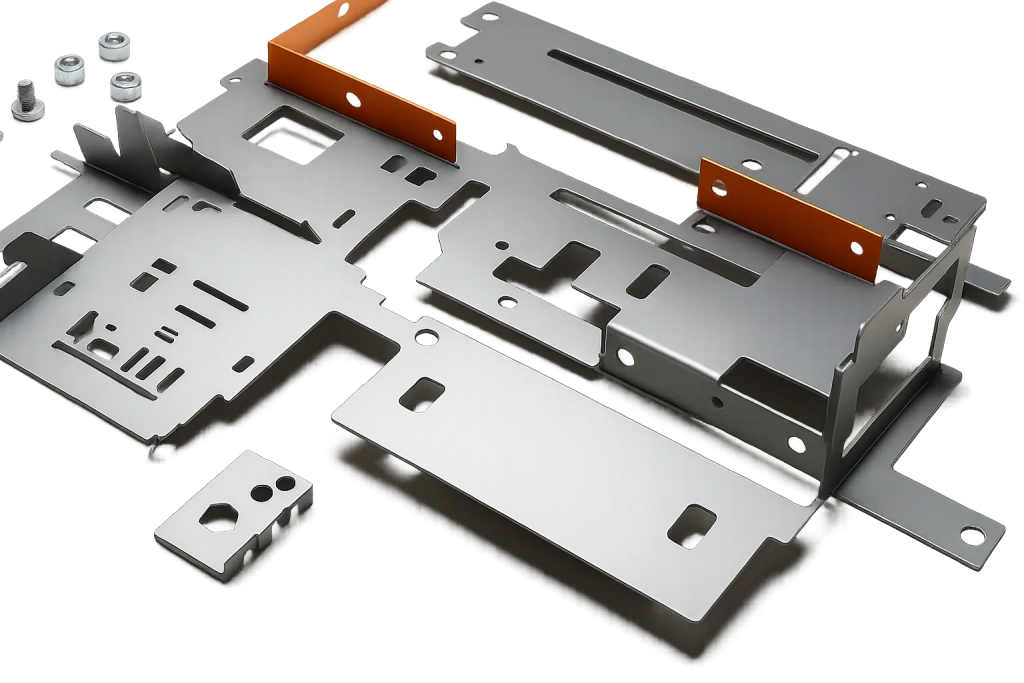

Optimized Aluminum Sheet Metal Parts for Lightweight, Durable, and Cost-Effective Fabrication

Aluminum sheet metal fabrication applies CNC precision to create lightweight, corrosion-resistant parts with tight tolerances. Its superior machinability and strength-to-weight ratio make it a preferred choice for high-performance components in aerospace, automotive, and hygienic environments.

NDA available upon request before quoting.

Aluminum in Sheet Metal Fabrication

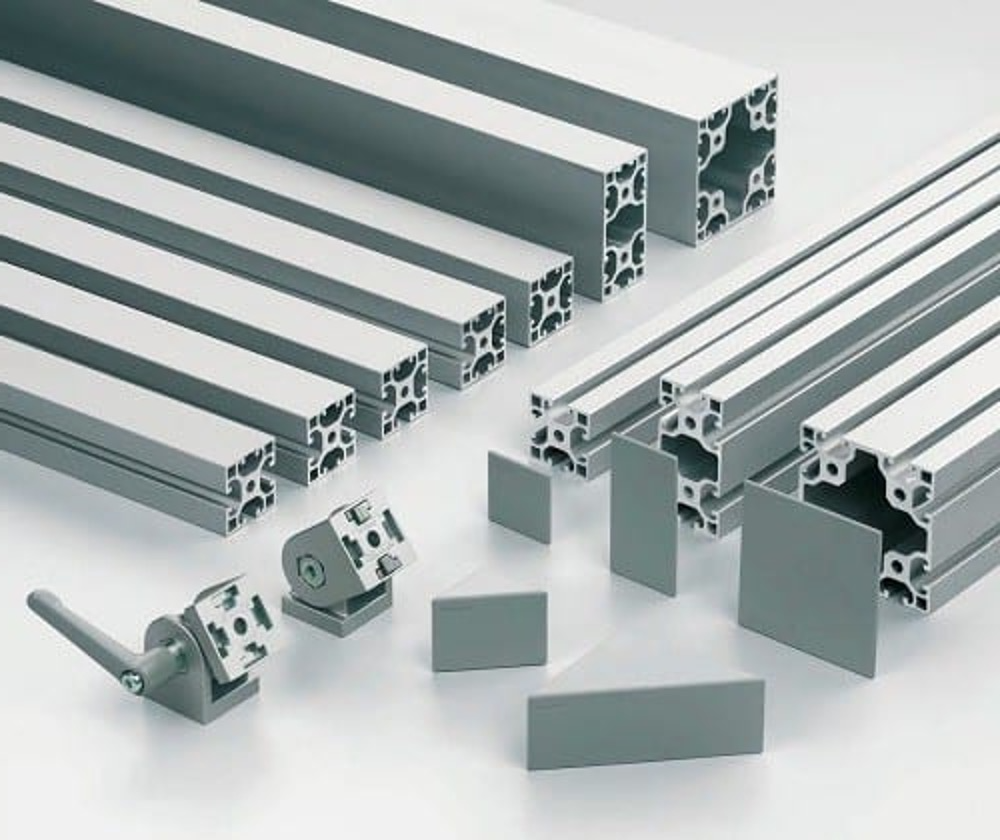

Aluminum is a favored material in sheet metal fabrication due to its lightweight properties, excellent corrosion resistance, cost-effectiveness, and varied grade availability. The fabrication process involves shaping aluminum sheet material through methods such as cutting, welding, forming, bending, and joining—techniques selected based on the specific requirements of the application. Due to its versatility, aluminum sheet parts are utilized across a broad range of industrial sectors, from aerospace and automotive to food processing. In most cases, processes like forming and cutting are critical initial steps in producing high-performance aluminum components.

Aluminum Grades Used in Sheet Metal Fabrication

Aluminum 6061 (T6/T651):

A heat-treated structural alloy popular in aviation for its strength and corrosion resistance.

Although it offers moderate formability and weldability, it is extensively used in boats, automotive components, and bicycles due to its robust performance and durability.

Aluminum 5052 (H32):

Provides significantly higher strength than 6061 while maintaining excellent weldability, formability, and corrosion resistance.

Ideal for demanding applications such as tanks and chassis where robust performance and structural integrity are essential.

Aluminum 1100 (H14):

Recognized for its outstanding ductility and exceptional weldability, making it highly suitable for deep drawing and forming processes.

Despite its lower strength, its economic purity, along with strong resistance to chemicals and weather, makes it a preferred choice for chemical processing applications.

Aluminum 3003 (H14):

Offers a balance of improved strength over 1100 while retaining high malleability, weldability, and corrosion resistance.

Commonly used in storage solutions such as cabinets and tanks, and well-suited for stamping and drawing operations.

Benefits of Aluminum Sheet Metal Fabrication

Weight Reduction:

Aluminum sheet metal parts effectively replace heavier materials, significantly reducing overall weight while preserving structural integrity.Enhanced Durability:

Aluminum exhibits excellent resistance to corrosion, heat, rust, and wear, ensuring long-lasting performance in demanding environments.Cost Efficiency:

As an economical material, aluminum offers a low-cost solution for sheet metal fabrication without compromising quality.High Formability:

Aluminum sheets can be easily cut, bent, stretched, or rolled into nearly any shape, providing exceptional design flexibility.Long-Term Stability:

Fabricated aluminum components maintain their shape and functionality for extended periods, even under challenging conditions.

Comprehensive Aluminum Sheet Metal Fabrication – Expert Manufacturer of Custom Aluminum Components

For projects requiring custom aluminum sheet metal fabricated parts, mazaro is your premier choice. With over 15 years of experience in metal machining and fabrication, we specialize in producing bespoke aluminum products tailored to your unique applications—whether for vehicle doors, medical equipment, digital devices, or consumer products.

Why Choose Mazaro Aluminum Sheet Metal Fabrication?

Expertise & Precision:

Our team of highly skilled engineers, technicians, and operators deliver outstanding craftsmanship, ensuring every component is produced with exceptional accuracy and precision.ISO 9001:2015 Certified Quality:

We adhere to rigorous quality assurance protocols and conduct strict inspections and testing, guaranteeing that each part meets or exceeds your specifications.Transparent Production Process:

We keep customers informed at every stage of the production cycle, ensuring complete visibility and confidence in our process.Flexible Manufacturing Capabilities:

From standard mechanical parts to intricate, custom shapes, our fabrication capabilities are designed to meet a diverse range of requirements while consistently delivering high-quality results.Comprehensive Services:

Beyond aluminum sheet metal fabrication, our state-of-the-art facility also handles a variety of metal and plastic processes, providing a one-stop solution for your manufacturing needs.