Precision Brass Sheet Metal Fabrication – Custom Alloy Solutions for Superior Performance

We employ CNC laser cutting, press braking, and automated welding to transform brass—an alloy prized for its corrosion resistance, electrical/thermal conductivity, and formability—into precision sheet-metal components

NDA available upon request before quoting.

Brass in Precision Sheet Metal Fabrication

Brass, a copper-zinc alloy, is prized in CNC sheet metal fabrication for its robust strength, high corrosion resistance, and excellent electrical conductivity. Its inherent material properties make it an optimal choice for both electrical applications and mechanical assemblies. Utilizing advanced CNC techniques—including precision cutting, bending, forming, and welding—fabricated brass components achieve high accuracy and finish quality. The unique zinc-to-copper ratio in various brass alloys allows for tailored mechanical and aesthetic properties, supporting a wide range of applications from gears, hinges, and handles to decorative elements and musical instruments.

Benefits of Brass Sheet Metal Fabricated Parts

Antimicrobial Properties: Inhibits the growth of viruses and bacteria.

Superior Formability: Easily bent and molded to conform to complex geometries.

High Thermal & Electrical Conductivity: Withstands elevated temperatures while maintaining excellent conductivity.

Excellent Corrosion Resistance: Ideal for harsh environments, making it suitable for aviation and naval applications.

Precision Engineering: CNC machining delivers accurate, high-quality components perfect for critical applications.

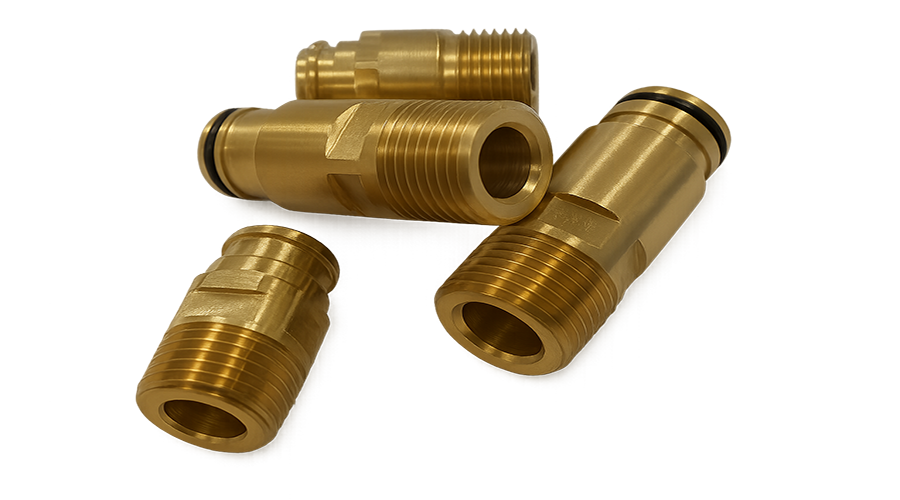

Enhanced Plumbing Integration: Brass fittings facilitate efficient, reliable plumbing connections.

Types of Brass Sheet Metal

Alloy C353 (Leaded Brass):

Containing up to 3.5% lead, C353 is engineered for pressure tightness via enhanced sealing and reduced shrinkage. This alloy is ideally suited for manufacturing screws, valves, fittings, bearings, specialty fasteners, architectural hardware, and general machine components using CNC precision techniques.Alloy C260 (Cartridge Brass):

Commonly known as 70/30, this copper-zinc alloy exhibits a warm yellow tone and is available in tube, sheet, and plate forms. Historically used in ammunition and cartridge applications, C260 offers excellent machinability and aesthetic appeal for various precision CNC-fabricated components.Alloy C464 (Naval Brass):

A time-tested alloy for maritime applications, C464 is noted for its high strength and robust corrosion resistance in both fresh and saltwater environments. Its properties make it ideal for CNC machining of propeller shafts, nautical hardware, ornamental fittings, and turnbuckles, ensuring durability under harsh marine conditions.

Brass Sheet Metal Fabrication Solutions – Your Expert Fabricator & Manufacturer for Custom Brass Components

Our brass sheet metal fabrication services deliver custom brass components with precise geometries and specifications tailored to your design requirements. Equipped with state-of-the-art CNC machinery and staffed by seasoned technicians, we ensure high efficiency, accuracy, and quality in every project—from the smallest brass parts to the largest workpieces. Utilizing advanced processes such as laser cutting, sawing, shearing, punching, and bending, we transform your designs into finished products that meet rigorous manufacturing standards. Additionally, our comprehensive metal finishing services provide a premium, attractive surface that enhances both the appearance and performance of your brass components, all offered at competitive prices with exceptional service.

Why Choose MazaroMazaro Brass Sheet Metal Fabrication Services?

Standards & Customization:

We consistently meet and exceed rigorous industrial standards while accommodating your specific design requirements.Skilled Workforce:

With over 100 highly skilled employees, including dedicated CNC professionals, we ensure precise and efficient production.Comprehensive Fabrication Capabilities:

Our extensive range of brass sheet fabrication services addresses diverse needs, from basic cutting and forming to complex custom projects.Value-Added Services:

In addition to fabrication, we offer advanced machining and precision surface finishing solutions tailored to elevate your product performance.Technical Expertise:

Our talented engineers provide continuous support and technical guidance throughout the entire production process, ensuring optimal results.