Manufacturing Quality Assurance

- Thorough Real-Time Production Inspections

- Conclusive Product Verification and Quality Testing

- Continuous Process Enhancement via Closed-Loop Feedback

- Supplier Material Verification and Full Traceability

NDA available upon request before quoting.

We ensure superior customer satisfaction by implementing quality control and assurance through

Certified to ISO 9001:2015, our quality system embeds preventive controls throughout the CNC workflow—from process capability studies and scheduled machine maintenance to advanced in-process probing and CMM inspections. We leverage real-time SPC monitoring and continuous training to anticipate and eliminate issues before they occur. This relentless focus on precision and improvement ensures every component delivers exceptional quality, performance, and cost efficiency.

Quality Assurance & Control Framework

In precision CNC manufacturing, quality control serves as our first line of defense—starting with incoming material verification, continuing through real-time in-process metrology, and concluding with final CMM inspections. This rigorous, end-to-end approach ensures every component not only meets but often exceeds stringent industry tolerances, safeguarding both product integrity and our reputation for engineering excellence.

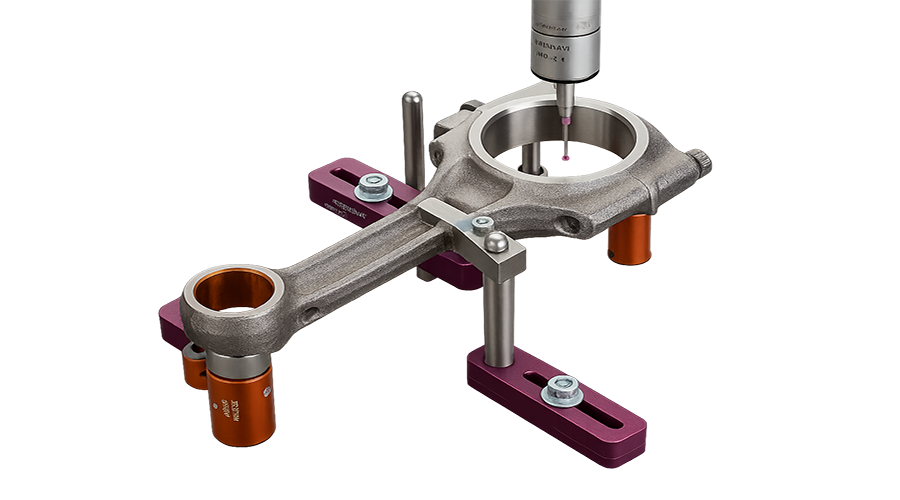

Coordinate Measuring Machine

Our CMM (Coordinate Measuring Machine) combines high-precision probes with multi-axis movement to capture discrete spatial coordinates on machined parts. By mathematically analyzing these data points, we perform rigorous dimensional inspections and geometric validations—ensuring every component adheres to your tightest tolerances and quality standards.

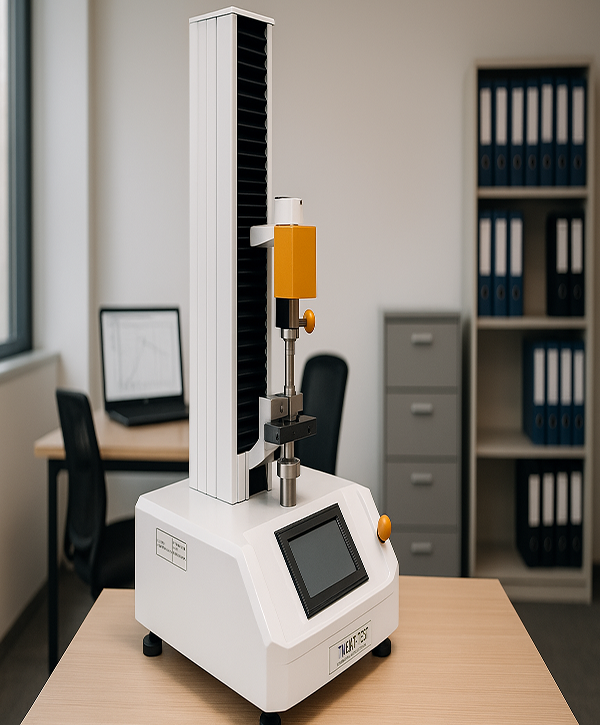

High Gauge

Our high-precision height gauge delivers rapid, automated dimensional checks for both individual and mass-production parts. Equipped to measure vertical heights, depths, slot widths, inner/outer diameters, hole-center and axis-center distances, flatness, and perpendicularity, it integrates seamlessly into CNC workflows for real-time quality assurance. By ensuring every critical dimension is verified on-line, our gauge system enhances throughput, reduces scrap, and upholds the tightest tolerances—delivering unmatched reliability for your production needs.

Profile Projector

Our advanced contour measurement system captures detailed profiles of molded parts, verifying complex geometries against tight tolerances with micrometer-level accuracy.

| Inspection Type | Quality Inspection | Digital Inspection | Conventional Inspection |

|---|---|---|---|

| Ideal For | Confirming the integrity of Protolabs’ manufacturing processes | Checking up to 50 critical dimensions in a cost-effective and timely manner | Measuring any number of dimensions, including non-critical aspects |

| Measurement Capabilities | Up to 4 plane-to-plane and outside diameter (OD) measurements | Up to 50 measurements, including OD/ID, plane-to-plane, hole location, and angles | Unlimited measurements utilizing most GD&T types |

| Special Features | Includes images highlighting quality checks | Digital reports featuring color mapping or a standalone color map option | None |

| Who Can Use It | Applicable to all injection molding and CNC machining orders | Suitable for on-demand manufacturing and injection molding orders | Also available for on-demand manufacturing and injection molding orders |

| Lead Time Requirements | No additional lead time | Usually requires an extra 3+ days | Typically takes 7+ days |

| Cost Structure | No extra charge required | Additional fees may apply; please consult your account representative for specifics | Additional fees may apply; consult your account representative for details |

| Sampling Plan | Molding: Initial part checked at start of the run and approximately every 12 hours for longer runs; Machining: All parts will be checked |

Molding: Randomly selected parts per customer request; Machining: N/A | Molding: Random selection per customer request; Machining: N/A |

| Request Process | Automatically included with all on-demand manufacturing orders; for other inquiries, please contact customer service | Available with all on-demand manufacturing orders, or you can call your account representative to request | Accessible with all on-demand manufacturing orders or through your account representative |

| Important Note: For parts that exceed 8 inches (203mm) in diameter or 5 inches (127mm) in height, a conventional inspection is required. | |||

Moisture Analyzer

Determines the moisture level in materials to help avoid defects that can occur from excessive moisture during the injection molding process

XRF Analyzers

Identifies the presence of specific metals—such as aluminum, copper, and others—in products or raw materials

Color Controller

Verifies whether the color of raw materials or plastic parts aligns with the customer’s specified requirements

Quadratic Element Vision Measure

Measures the size and shape (position, straightness, roundness, etc.) of products or molds, mainly for flat, thin, or small parts

Pressure Gauge

Measures the size and shape (position, straightness, roundness, etc.) of products or molds, mainly for flat, thin, or small parts

Profile Projector

Provides high-precision measurement of molded parts’ shapes and outlines, ensuring even intricate geometries conform to specifications