Precision Copper Sheet Metal Fabrication – Custom High-Performance Solutions

Leveraging copper’s exceptional electrical and thermal conductivity—second only to silver and gold, respectively—our CNC sheet metal fabrication transforms ductile, corrosion-resistant copper alloys into precision parts with tight tolerances.

NDA available upon request before quoting.

Advanced Copper Sheet Metal Processing

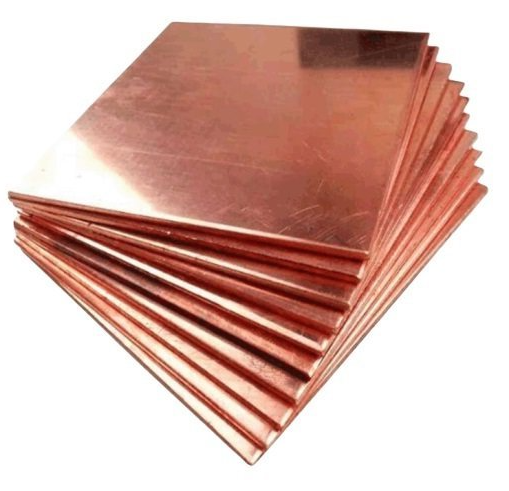

Copper sheet metal fabrication utilizes a variety of copper alloys, each selected for its distinct properties. Pure copper exhibits a light red hue that evolves to a purplish red once an oxide film forms on the surface. Renowned for its outstanding electrical conductivity—second only to silver—and exceptional thermal conductivity, which is surpassed only by gold and silver, copper also demonstrates excellent chemical stability, corrosion resistance in atmospheric, freshwater, and seawater environments, and high ductility that permits robust cold and hot pressure processing. Although its inherent low strength and hardness limit its use in structural applications, these characteristics make copper one of the most versatile and easily fabricated materials in sheet metal production. As a result, copper sheet metal components are extensively employed in a range of industries including chemical processing, aerospace, automotive, and beyond, ensuring efficient and high-precision outcomes through CNC fabrication processes.

Benefits of Copper in Sheet Metal Fabrication

Superior Conductivity:

Exhibits exceptional thermal and electrical conductivity, ideal for applications requiring efficient heat dissipation and reliable electrical performance.Robust Chemical Stability:

Demonstrates excellent resistance to corrosion and oxidation, with a low melting point that facilitates efficient processing.High Formability:

Its impressive ductility allows for seamless forming, cutting, bending, and stamping during CNC machining processes, outperforming materials with lower plasticity.Versatile Processing:

Capable of enduring both cold and hot fabrication methods, ensuring reliable performance during various sheet metal operations.Sustainability & Cost Efficiency:

Easily recycled without significant degradation of quality, and offers a more cost-effective solution compared to many alternative sheet metals.

Copper Alloys Used in Sheet Metal Fabrication

Copper alloys used in sheet metal fabrication typically feature over 99% copper with trace impurities. Two primary grades include:

C101 (Oxygen-Free Copper, 99.99% Cu):

Exhibits exceptional electrical conductivity and high ductility.

Work-hardens slowly, allowing for improved formability via annealing.

Ideal for electrical applications such as grounding strips, anodes, and circuit breakers.

C110 (ETP Copper, 99.90% Cu):

Widely available and commonly used.

Optimized for both electrical and thermal applications, including heat exchanger fins and electrical switches.

High-Quality Copper Sheet Metal Fabrication Solutions – Trusted Manufacturer of Custom Copper Components.

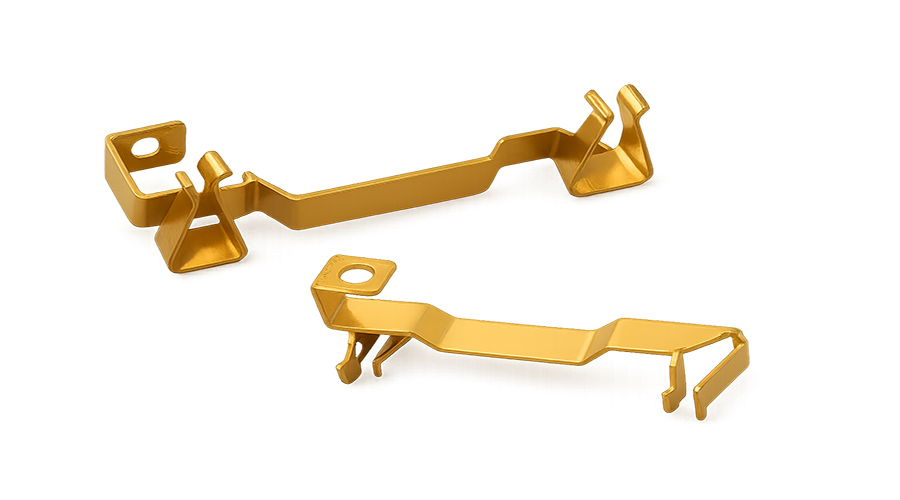

Copper sheet metal is highly valued in industrial production for its exceptional flexibility and corrosion resistance. As a specialized metal machining and fabrication company, Junying delivers comprehensive copper sheet metal fabrication services, capable of producing components in nearly any size and shape required—whether for decorative purposes or demanding industrial applications. Our offerings predominantly utilize C101 and C110 copper grades, while also accommodating other copper alloys to suit specific project needs. We manufacture a broad array of custom parts, including plates, fixtures, shields, and brackets, using advanced techniques such as laser cutting, punch pressing, and tube bending. Whether you need a single prototype or large-scale production, our state-of-the-art facility and expertise ensure precision and quality for every copper sheet metal solution.