High-Accuracy CNC Machining Solutions with Rigorous Quality Assurance

Our CNC precision machining service exceeds standard processes by employing state-of-the-art machining centers combined with advanced surface-polishing systems to deliver unrivaled detail and finish quality.

NDA available upon request before quoting.

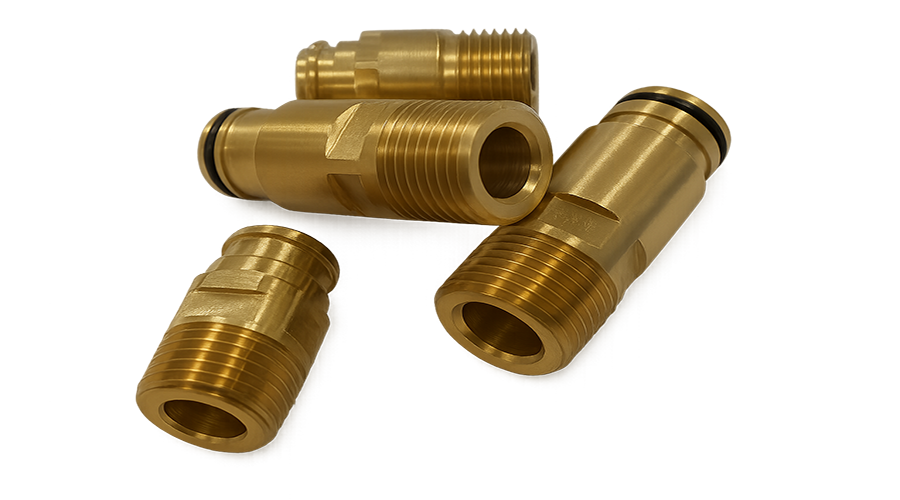

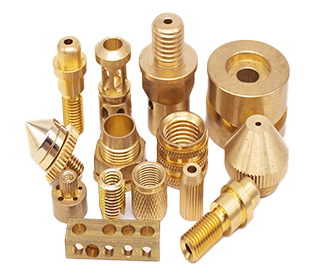

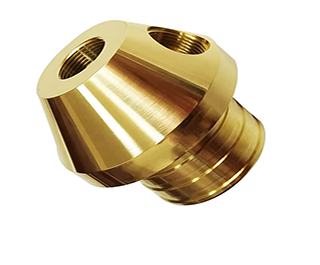

CNC brass material processing

Brass, an alloy of copper and zinc, is renowned for its exceptional wear resistance, low coefficient of friction, low melting point, excellent malleability, and high corrosion resistance. These properties make brass particularly suitable for high-temperature applications and heavy-duty machinery. Consequently, brass is an ideal material for CNC machining, where precision-crafted parts are critical. Precision-machined brass components are widely utilized in manufacturing valves, water pipes, air conditioning connectors, and radiators, and are also prevalent in electrical products, plumbing systems, the medical sector, and various consumer goods.

Brass Precision CNC Machined Components – Premier China CNC Brass Parts Supplier

Are you in need of precision-machined brass components from a trusted and experienced CNC manufacturer? mazaro offers custom brass machining services with over 10 years of industry expertise. Our state-of-the-art facility is fully equipped to produce both simple and complex brass products, including high-precision CNC milled, turned, and drilled components, tailored to your exact requirements.Our brass components are non-magnetic, exhibit excellent castability, and typically do not require additional surface finishing. Each part undergoes a stringent quality control process, featuring designated inspections, in-process monitoring, and comprehensive final assessments, ensuring superior performance and reliability.

Features & Advantages of Custom Machined Brass CNC Components

- Enhanced Sealing: Brass components offer superior sealing capabilities, ensuring tighter fittings and leak-proof performance.

- Cost Efficiency & High Strength: They help reduce production costs while delivering exceptional strength under high-stress conditions.

- Temperature Resilience: Engineered to endure extreme temperature variations, brass parts maintain their integrity under harsh conditions.

- Excellent Castability: The material’s high castability enables the production of complex, precision components.

- Superior Durability: With high heat and corrosion resistance, brass components are rustproof and exhibit a premium, long-lasting performance.

- Lightweight & Easy Installation: Their low weight facilitates efficient handling, transportation, and installation, making them ideal for various applications.

Below is a classification of common brass grades along with their key features:

C36000 (Free-Cutting Brass):

Key Features:

Excellent machinability with high cutting performance, ideal for precision CNC machining

Superior surface finish with minimal tool wear

Commonly used for manufacturing precision components and fittings

C26000 (Cartridge Brass):

Key Features:

High ductility and good formability, suitable for cold working and deep drawing

Outstanding corrosion resistance, adaptable to various environments

Frequently used in springs, bushings, and electrical connectors

C46400 (Marine Brass):

Key Features:

Exceptional resistance to seawater corrosion, making it ideal for marine and harsh environment applications

Enhanced mechanical performance and wear resistance

Often applied in marine hardware and related components

C27000 (Architectural Brass):

Key Features:

Bright and attractive appearance with excellent decorative qualities

Good corrosion resistance, perfect for architectural and decorative applications

Commonly utilized in building hardware, door and window fittings

C22000 (Red Brass):

Key Features:

High copper content provides superior corrosion resistance

Balanced machinability for a range of standard applications

Often used in piping, marine equipment, and other industrial applications