mazaro precision steel CNC machining services and customized machined parts services

Global Quality Standards: Our internationally recognized quality certifications empower us to export precision CNC-machined steel and metal products worldwide.

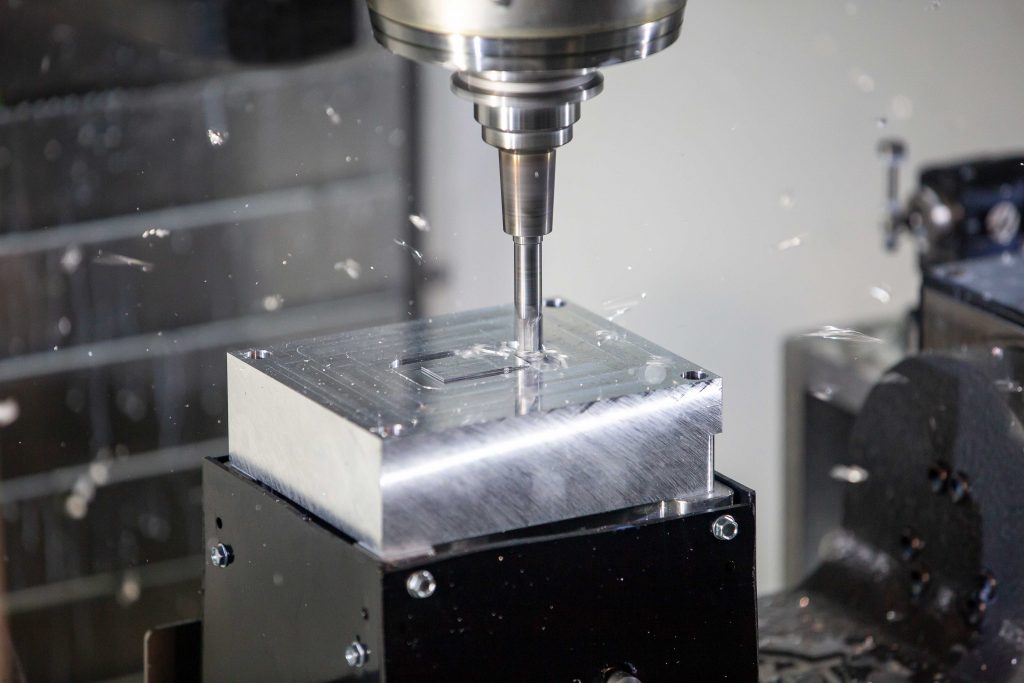

Advanced Production Capabilities: Cutting-edge equipment, modern machinery, and a skilled workforce ensure consistent high productivity and quality.

Proven Industry Expertise: With over 15 years of experience serving diverse industries and markets, we deliver solutions that meet the most stringent standards.

- Strategic Location: Our prime geographic position optimizes logistics and accelerates delivery times for global shipments.

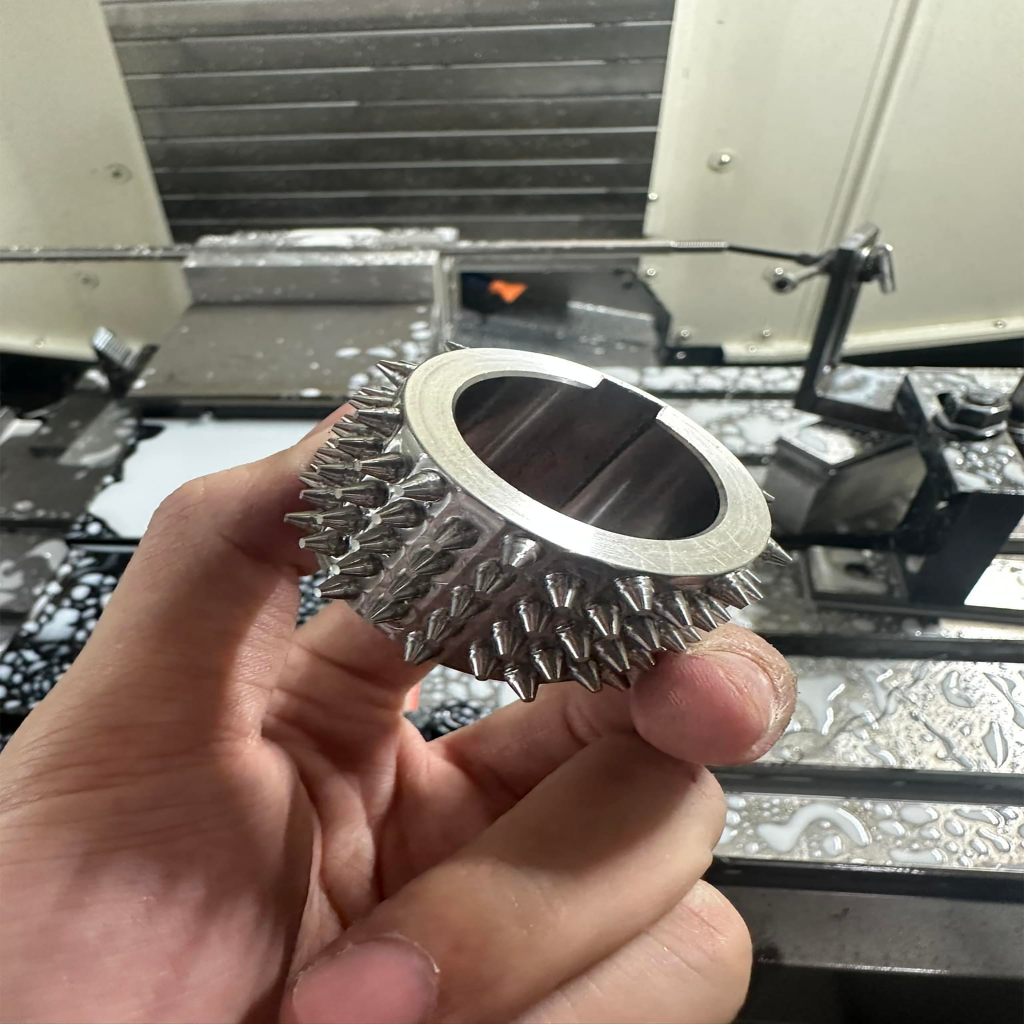

Our state-of-the-art machine shop and advanced manufacturing facilities empower us to produce custom CNC steel parts with both simple and complex geometries. We employ a broad range of precision machining technologies—including milling, turning, drilling, wire EDM, and grinding—complemented by superior finishing and additional fabrication methods. Whether your project demands high precision, repeatability, or tight tolerances, our steel components are engineered to meet your exacting specifications.

CNC Machining in Steel – Steel Properties and Benefits

Steel serves as the cornerstone for engineering and industrial applications, making it a prime choice for precision CNC machining—particularly in the realm of low-carbon and medium-carbon steels. As an alloy primarily composed of iron and carbon, steel is enhanced with elements such as manganese, silicon, phosphorus, and oxygen, which collectively improve its mechanical properties. The carbon content notably increases its strength and fracture resistance, ensuring robust performance under stress.Moreover, steel exhibits excellent machinability, weldability, and heat-treatability, allowing for the production of components with tight tolerances and high durability. These attributes make steel the preferred material in high-performance sectors such as automotive and aerospace, where CNC machining is the manufacturing method of choice for achieving reliable, cost-effective, and high-quality results.

Steel Alloys in Precision CNC Machining: Exploring Types, Grades, and Applications

Steel 4130: A low-carbon, chromium-molybdenum alloy with a density of 7.85 g/cm³, 4130 steel benefits significantly from heat treatment hardening. In its annealed state, it offers excellent machinability for both hot and cold processing, along with exceptional strength, weldability, and resistance to abrasion and impact. However, machining becomes more challenging post-hardening. It is ideally used in high-performance applications such as bearings, vehicle components, gears, structural elements, and cutters.

Steel 4140: This low alloy steel, enhanced with chromium, molybdenum, and manganese, is known for its superior toughness, fatigue resistance, and torsional strength. With a higher carbon content than 4130, 4140 exhibits increased strength and hardening potential, though this also results in increased brittleness. Its enhanced mechanical properties make it suitable for demanding applications, including thin-walled pressure vessels, spindles, and high-strength fasteners.

Steel 1018: A low-carbon mild steel recognized for its excellent ductility, toughness, and strength, 1018 is highly compatible with various welding techniques and CNC machining processes. Its properties support effective case hardening and high surface hardness, making it an excellent choice for producing components such as worms, dogs, pins, liners, machinery parts, specialized bolts, ratchets, chain pins, oil tool slips, tie rods, anchor pins, and studs. This versatility enhances operations like drilling, milling, threading, and punching.

Steel A36: Widely used in structural applications across the United States, A36 steel is a low-carbon alloy available in various forms such as plates, structural shapes, bars, girders, and angle irons. Its low-carbon composition ensures ease of machining, welding, and forming, making it a reliable general-purpose steel. Additionally, its minimal sensitivity to heat treatment allows for consistent performance, making it an optimal choice for a broad range of structural and fabrication projects.